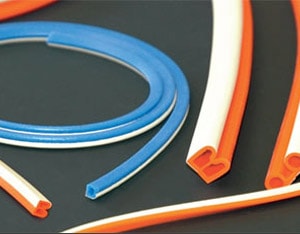

High Performance Elastomeric Gaskets, Seals, Tubing, Moldings, & EMI/RFI Shielding Gaskets

Vanguard Products Corporation is a full service manufacturing and engineering company providing industry with the highest quality elastomeric goods available.

With our in-house compounding and mixing, our focus is on high performance elastomers such as silicone, fluorosilicone, fluorocarbon (Viton®, Fluorel®, etc.), EPDM, nitrile (Buna-N), and chloroprene (Neoprene®) in both sponge and dense elastomer forms for sealing, fluid transfer, shock absorption, heat transfer, and EMI/RFI shielding applications.

Standard and custom products are available along with custom finishing services.