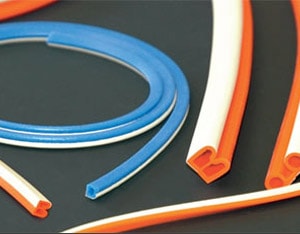

Vanguard Products Corporation is a global supplier of various EMI/RFI shielding gaskets and conductive gaskets. These products can be customized based on the needs of our customers, with numerous material options and sizes ranging from 0.010’’ to 3’’ in cross-section. We are ISO 9001:2015 certified, and our EMI shielding gaskets are UL-listed, have low compression force and flame retardant properties, and exhibit the highest level of shielding and mechanical/environmental sealing. We also offer Mil-Spec EMI/RFI shielding gaskets that comply with MIL-DTL-83528 for use in various military applications.

EMI/RFI Shielding Gasket Overview

EMI shielding gaskets are designed to protect electronic equipment from harmful electromagnetic interference (EMI) and radio frequency interference (RFI). By creating a conductive path along the seams and other openings in an electronic enclosure, these gaskets establish smooth current flow and prevent destructive radiation from interfering with performance by completing a Faraday cage around the electronics.

EMI/RFI disturbances can destroy or disrupt electrical circuits, making EMI/RFI shielding gaskets a necessary component for a wide range of electrical equipment. There are many types of EMI/RFI shielding gaskets on the market, and they can be made from many materials, including plastic, foam, metals, and elastomers. It’s important to understand the various types so that you can select the appropriate shielding solution for your application.

Types of EMI Gaskets

To suit different applications, industries, and environmental conditions, Vanguard offers the following types of EMI/RFI shielding gaskets and conductive gaskets:

Silicone EMI Gaskets:Silicone is an ideal gasket material because it offers resistance to high and low temperatures as well as excellent tensile strength, compression set, and tear strength. This long-lasting material is also resistant to aging, fire, water, ozone, chemicals, and fungal growth. Generally, silicone EMI shielding gaskets are the right choice for most applications and industries; however, EPDM or fluorosilicone may be the superior option for more demanding environments.

EPDM EMI Gaskets:

EPDM has a higher tensile strength than silicone. It also functions well in high and low temperatures and offers resistance to abrasion, oxidation, ozone, UV, acids, alkalis, water, and harsh weather conditions. The properties of EPDM make it ideal for outdoor environments, military applications, and other complex settings.

Fluorosilicone EMI Gaskets:

Fluorosilicone is resistant to oil, fuel, chlorinated and aromatic hydrocarbons, UV, and ozone. It also features a good compression set and can perform well over a broad range of temperatures. Because of their material properties, fluorosilicone EMI shielding gaskets are popular for aerospace and military electronics as well as other demanding applications.

Dual Elastomer EMI Shielding Gaskets

Vanguard is a registered manufacturer with The United States Department of State, Office of Defense Trade Controls Compliance, Compliance and Registration Division, pursuant to The Arms Export Control Act (AECA) and the International Traffic in Arms Regulations (ITAR Part 122). Our VanshieldTM, Ultra-Vanshield™ and MICROBRIDGE™ shielding gaskets are made with quality silicone, EPDM, and fluorosilicone materials and comply with MIL-DTL-83528 for use in a wide range of mission-critical applications. Our capabilities include in-house formulation, mixing, and testing, as well as secondary operations such as cutting, bonding, and O-ring fabrication.

Common uses for our standard and custom Dual Elastomer EMI shielding gaskets include:

- Military Electronics

- Medical Electronics

- Computers

- Indoor/Outdoor Cellular/Telecom Base Stations

- High-Speed Electronics

- TENS Electrodes

- Automotive Control Systems

- Shielded Connector Seals

- Military Weapons Systems

- Avionics

- Communications Systems

Advantages of our Ultra-Vanshield™ and MICROBRIDGE™ Duel Elastomer Shielding Gaskets include:

- Broad environmental protection (NEMA, IP, wind-driven rain, immersion, etc.)

- Consistent attenuation performance (even under full compression)

- Easier termination

- Excellent conductive properties

- Extended galvanic protection

- Manufacturing flexibility

- More resilient inner cores that do not contain or accrue metal fillers

- Single unit EMI Seals (weatherproofing)

- Silver conductive material limited to only a thin, outer membrane (reducing cost)

- Superior compression and aging properties

- Very low compressive forces

Our MICROBRIDGE™ gaskets also offer even lower silver contents for additional cost savings as well as moisture sealing on both sides of the conductive portion for better galvanic protection.

Factors To Consider When Designing EMI Shielding

When designing the proper EMI shielding gasket for a particular application, there are many important factors to consider. For example, different applications have varying requirements for mechanical durability and attenuation level. Another important factor to consider is compression. Since compressive force has a significant effect on shielding characteristics, most applications require gaskets with low compression set to ensure long-lasting performance.

It’s also important to consider galvanic compatibility between the substrate metal and the conductive gasket material. If the materials are not compatible, the gasket could form a galvanic cell which could lead to corrosion.

EMI Shielding Gaskets from Vanguard Products Corporation

Vanguard specializes in providing customized solutions to meet the varying requirements of numerous applications. We focus on identifying alternative materials and production approaches to cut costs while enhancing performance. To learn more about our EMI shielding and conductive gasket solutions, or for help selecting the right gasket for your sensitive electronic application, contact our experts today.