Rubber molding is a manufacturing process that involves injecting or pressing rubber into molds and curing it to hold the desired shape. It is used to produce a wide range of parts and products for various industries and applications, such as O-rings, gaskets, and seals. One of its key advantages is three-dimensional shapes, which makes it easier for manufacturers to configure the product to their needs.

Looking for a partner for your next custom molded rubber project? Turn to the experts at Vanguard! By choosing to work with us, you benefit from our:

- Specialization in application assistance, including identifying alternative cost-saving production approaches

- High-precision, cost-efficient production operations in a USA-based, ISO 9001:2015-certified manufacturing facility

- Custom compound formulation capabilities for precision engineered performance and optimized cost

- Extensive in-house secondary processing capabilities, such as cutting, bonding, adhesive application, and frame and O-ring fabrication

- Manufacturing capacities for profiles and configurations ranging from simple to complex in high or low volume quantities

- Complete one-stop-shop experience for extruded and molded products in various engineering elastomers with extensive engineering support

Why Choose Custom Molded Rubber Components?

Custom molded rubber components offer numerous advantages over parts and products made through alternative rubber manufacturing methods. For example:

- Greater precision. Many applications for rubber components involve tight tolerances. Whereas some rubber manufacturing methods cannot produce pieces that meet the requirements and restrictions of these use cases, rubber molding can produce ones that are both durable and more precise than other production methods.

- Better performance. Custom molded rubber components are designed and built to meet the needs of the applications. As a result, they will fit and perform exactly as intended.

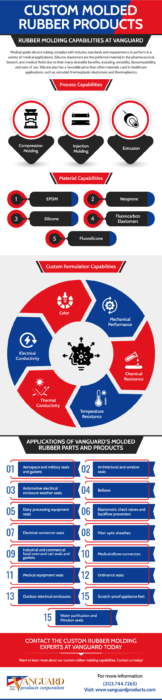

Rubber Molding Capabilities at Vanguard

Process Capabilities

Rubber product manufacturers use a variety of processes to create components. Some of the most commonly utilized are:

- Compression molding. In this molding process, uncured rubber is typically pre-measured and pre-shaped to a specific weight. It is then placed into an open mold. After the mold is closed, it is pressure, which causes it to flow, filling the mold cavity. Once formed, energy is applied, usually in the form of heoat, and the elastomer is cross-linked and cured into the desired shape.

- Injection molding. This molding process involves injecting cooled, degassed liquid rubber into a mold under pressure, and curing it to hold the mold shape.

- Extrusion. This forming process is distinct from molding processes. Rubber is forced through a die, which forms it into long pieces with a continuous cross-section.

At Vanguard, we offer a range of elastomeric molding capabilities, including compression molding, transfer molding, liquid injection molding (LIM), and insert molding.

Material Capabilities

Molded rubber components can be made from a number of materials to suit different applications. For example:

- EPDM offers strong ozone and UV resistance in a broad range of temperatures, which makes it suitable for the manufacture of outdoor components.

- Neoprene is an excellent general-purpose rubber. However, it is not suitable for applications where it will be exposed to strong chemicals.

- Silicone is available in high-purity variations, which are perfect for use in sensitive applications, such as those in the food, medical, and pharmaceutical industries. Silicone has the broadest temperature range among elastomers, performing in temperatures as low as -100°F to +450°F

- Fluorocarbon elastomers are ideal for components that will be exposed to strong chemicals and/or high temperatures (up to 350° F).

- Fluorsilicone has much the same mechanical and temperature resistance properties as silicone, but has the added benefit of being extremely resistant to hydrocarbon exposure. Our rubber molding experts use a variety of quality materials to manufacture custom molded rubber parts and products for our customers. Our broad material inventory ensures we can provide an appropriate solution for nearly any application, industry, or environment.

Not sure which material is best for your project? We’ll help you select or develop the right one for your needs. Our custom formulation capabilities enable us to target many material properties, including:

- Mechanical performance

- Chemical resistance

- Temperature resistance

- Thermal conductivity

- Electrical conductivity

- Color

We can also help with adhesive application, special put-ups, specialty packaging, and PSA application.

Applications of Vanguard’s Molded Rubber Parts and Products

Our custom molded rubber products and goods find use in applications and industries across the world. We can design and manufacture components that meet virtually any requirement and restriction, including:

- Aerospace and military seals and gaskets

- Architectural and window seals

- Automotive electrical enclosure weather seals

- Bellows

- Dairy processing equipment seals

- Elastomeric check valves and backflow preventers

- Electrical connector seals

- Fiber optic sheathes

- Industrial and commercial food oven and cart seals and gaskets

- Medical elbow connectors

- Medical equipment seals

- Ordinance seals

- Outdoor electrical enclosures

- Scratch-proof appliance feet

- Water purification and filtration seals

Contact the Custom Rubber Molding Experts at Vanguard Today

Want to learn more about our custom rubber molding capabilities. Contact us today! If you have an upcoming project and want to partner with us, request a video consultation to speak with one of our team members.