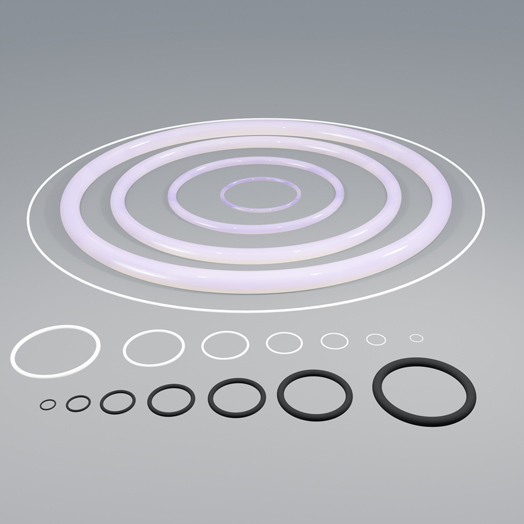

At Vanguard Products, we specialize in manufacturing and delivering high-quality O-rings made from specialized and food-grade materials. Our capabilities include an extensive range of molded rubber O-rings in standard AS568 sizes as well as more customized sizes. We also offer a variety of other seals, gaskets, and other related products. Our portfolio includes:

- AS568 O-rings

- EMI shield O-rings and seals

- O-ring cords

- O-ring kits

- Rubber strip material

- Spliced and vulcanized O-rings

- Other accessories

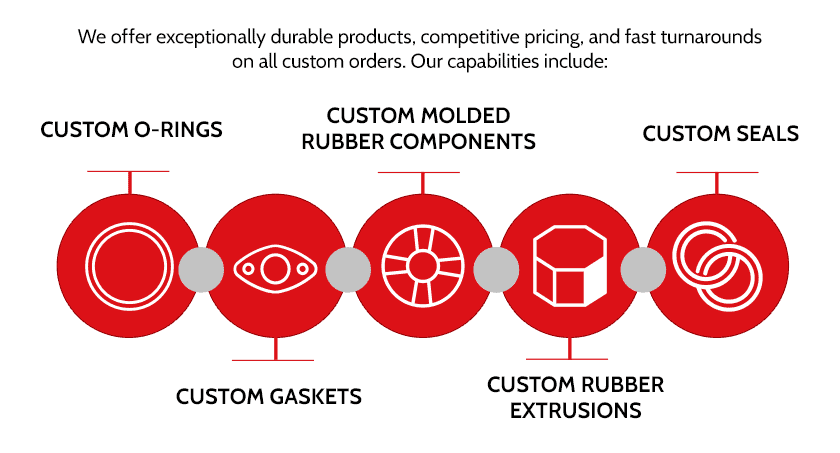

Along with our standard manufacturing, supply, and delivery services, our team can design and manufacture fully customized sealing components that meet specific application requirements, industry standards, and material needs. We offer exceptionally durable products, competitive pricing, and fast turnarounds on all custom orders. Our capabilities include:

- Custom O-rings

- Custom gaskets

- Custom molded rubber components

- Custom rubber extrusions

- Custom seals

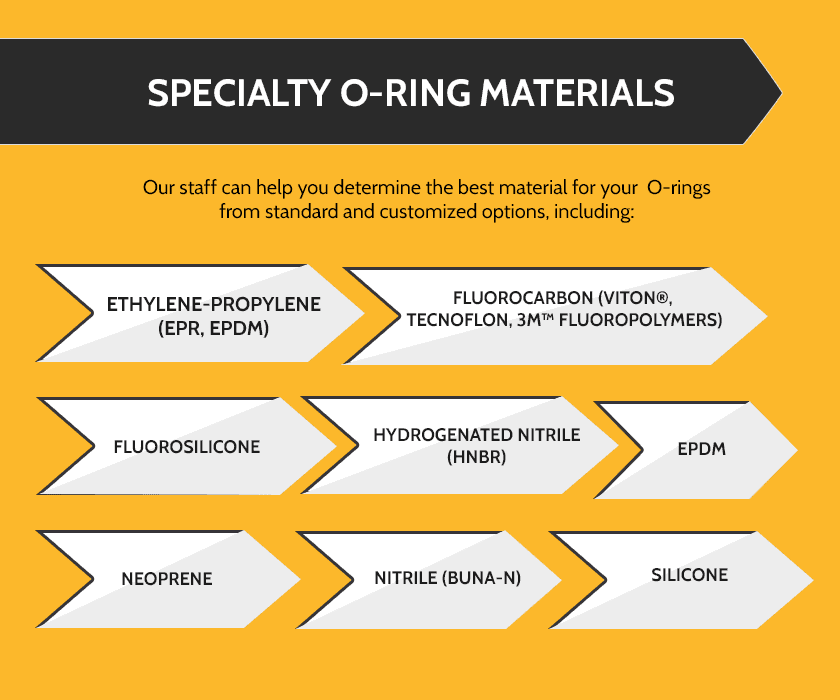

Specialty O-ring Materials

Industrial components must be made from materials that can handle the various challenges of the intended application. At Vanguard Products, we work with an extensive range of elastomers of varying hardness levels, offer custom rubber elastomer compounds, and offer a variety of specialty materials. Our staff can help you determine the best material for your O-rings from standard and customized options, including:

- Silicone

- EPDM

- Fluorosilicone

- Nitrile (Buna-N)

- Neoprene

- AFLAS®

- Ethylene-Propylene (EPR, EPDM)

- Fluorocarbon (Viton®, Tecnoflon, 3M™ Fluoropolymers)

- Hydrogenated Nitrile (HNBR)

- Perfluoroelastomer (FFKM)

Material Compatibility/Application Guidlines

O-ring Customization Examples

Custom O-rings typically need to meet exacting specifications and exceed the industrial guidelines used to fabricate more standardized sealing equipment. That’s why we offer custom material development and comprehensive design assistance to ensure end-to-end support that stems from design through the manufacturing and packaging stages. Customization options include:

- Chemical resistance

- Coatings and treatments

- Color

- Compliance with industry standards, including FDA, MIL-Spec, NORSOK M-719, NSF, USP, and more

- Durometer hardness

- Internal and/or surface lubrication

- Marking, labeling, kitting, and bagging needs

- Need for conductivity with EMI/RFI shielding

- Performance during extended periods at temperature extremes

Our custom manufacturing services may also incorporate specialty inspection procedures upon request. Our versatile equipment and capabilities can easily handle non-standard O-rings, including O-rings with internal compression holes and non-AS538 O-rings.

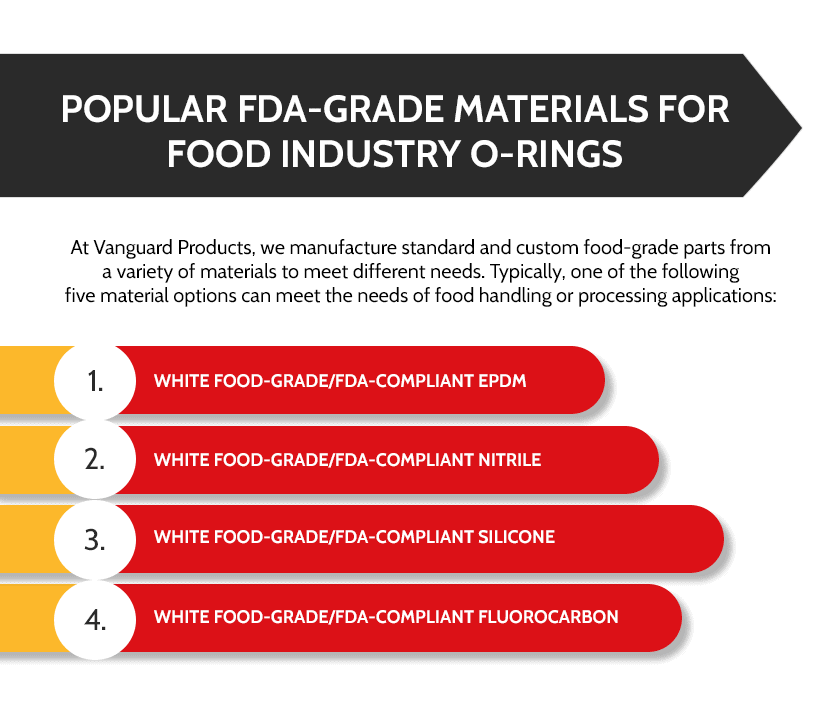

Popular FDA-grade Materials For Food Industry O-rings

The federal regulation 21CFR177.2600 details the U.S. Food and Drug Administration (FDA) requirements for component materials that come into contact with food and ingested materials. It is essential that components such as o-rings are consistent with these requirements.

At Vanguard Products, we manufacture standard and custom food-grade parts from a variety of materials to meet different needs. Typically, one of the following five material options can meet the needs of food handling or processing applications:

1. White Food-Grade/FDA-Compliant Silicone

The primary advantage of food-grade silicone is its chemical inertness. The material is entirely tasteless, odorless, peroxide-free, and non-toxic, which makes it ideal for use in food processing applications that directly contact consumable products. The material is also an excellent long-term choice because it doesn’t discolor or degrade due to chemical or thermal exposure. Its inherent resistance to electricity is another benefit. Silicone also resists fungus and bacterial buildup, making it a preferred choice for wet or damp applications.

2. White Food-Grade/FDA-compliant EPDM

Ethylene propylene diene monomer (EPDM) is an extremely popular and versatile rubber across food production and pharmaceuticals. It can handle a wide range of temperatures and is resistant to chemical damage or degradation from common materials. It’s ideal for use in food-contacting equipment that uses grease, oil, or phosphate esters.

3. White Food-Grade/FDA-Compliant Nitrile

Nitrile rubber (NBR) is a flexible, damage-resistant rubber. The food-grade variation of the material has the following benefits:

- Resists thermal damage from high temperatures, low temperatures, and temperature cycles

- Withstands daily cleaning processes

- Retains flexibility at different temperatures

- Resists damage from drops or impacts

- Resistance to damage or degradation from grease and oil

Some of the most popular food processing applications for FDA-compliant nitrile include cosmetics processing, pharmaceuticals, and food processing—especially in egg- and dairy-related applications.

4. White Food-Grade/FDA-Compliant Fluorocarbon

Fluorocarbon features an inherent resistance to chemicals and ozone attacks, so they can be used in harsh application environments. Other key benefits of food-grade fluorocarbon include chemical compatibility, a good temperature range, and a low compression set. Fluorocarbons age well, so these characteristics remain reliable throughout the service life of the component.

5. Neoprene

Neoprene was first created as an oil-resistant replacement for natural rubbers. Neoprene resists ozone damage, it has a long operating lifespan, and it is highly resistant to abrasion damage, making it ideal in food transport, storage, and mechanical applications. The smoothness of the material helps improve its resistance to oils and greases.

About Vanguard Products

At Vanguard Products Corporation, we prioritize product quality. All of our standard and custom components are handled by our in-house manufacturing and engineering teams to guarantee material quality and compliance with industry standards. All elastomeric fabricated products are made in the United States, and we’re an industry leader in creating high-precision components for industrial food processing and more.

Capabilities

We provide comprehensive engineering, manufacturing, and more. Our capabilities include the following:

- O-ring fabrication with inner diameter dimensions from 0.010″

- Numerous material options and color choices

- Multiple durometer hardness levels

- Bonding options

- Ability to create custom formulas to meet chemical resistance, temperature resistance, and mechanical needs

- Color-matching available for branding, organization, or other needs

- Thin-walled design options

- Special put-ups

- Pressure-sensitive adhesives

- Custom or specialty packaging

- Marking, labeling, kitting, and bagging

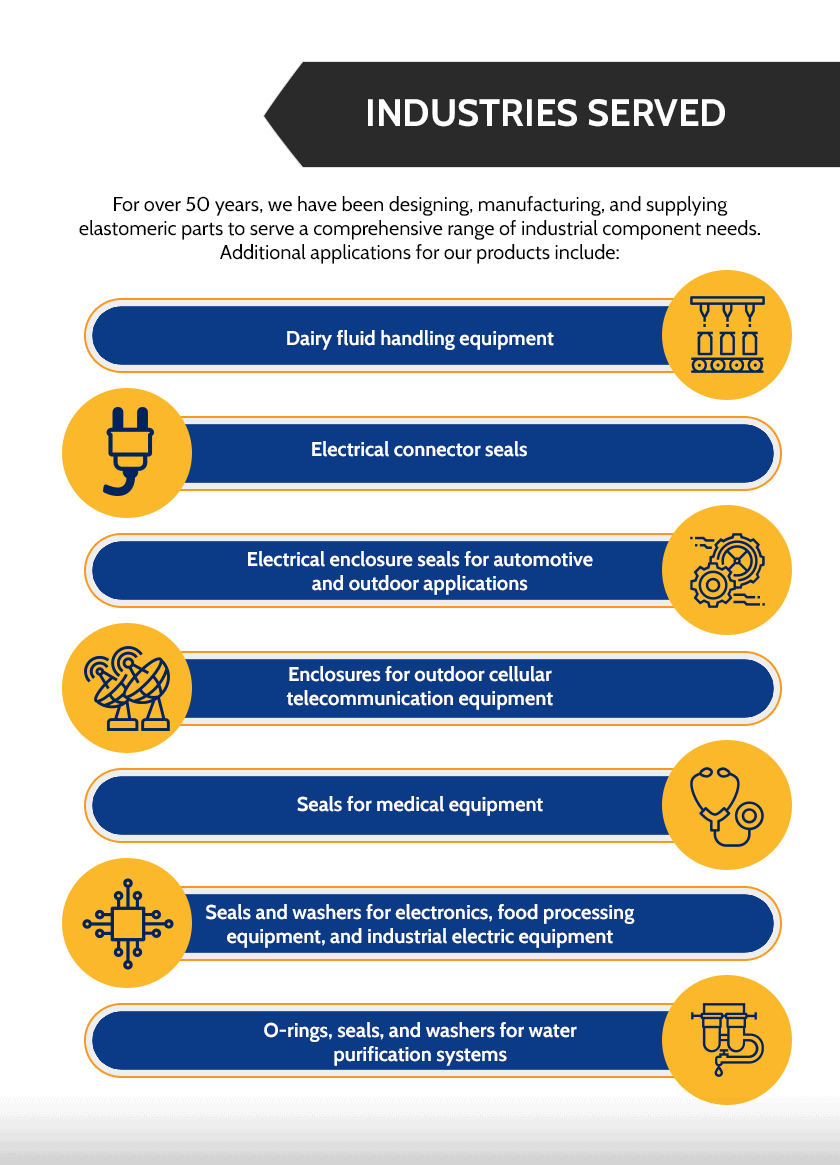

Industries Served

At Vanguard Product Corporation, we’re proud to serve an extensive range of industry needs. Our food-grade materials are used for food processing, pharmaceuticals, and personal care product manufacturing around the world. For over 50 years, we have been designing, manufacturing, and supplying elastomeric parts to serve a comprehensive range of industrial component needs. Additional applications for our products include:

- Dairy fluid handling equipment

- Electrical connector seals

- Electrical enclosure seals for automotive and outdoor applications

- Enclosures for outdoor cellular telecommunication equipment

- Seals for medical equipment

- Seals and washers for electronics, food processing equipment, and industrial electric equipment

- O-rings, seals, and washers for water purification systems

Visit our About Us page to learn more about our team and organization. To see how our food-grade O-rings or any of our other products can help you with your project or application, please contact us today.