An Overview of Rubber Tubing

At Vanguard Products Corporation, we specialize in engineering and manufacturing precision elastomeric fabricated goods. We offer an extensive selection of standard and custom extruded and molded gaskets, seals, and tubing. Below we provide an overview of rubber tubing, including types available, materials employed in the construction of the parts, and typical applications.

Manufacturing Considerations for Rubber Tubing

Rubber tubing is generally manufactured using extrusion processes. It is available in standard and custom variations to suit general and specialized use cases. If needed, custom sleeves can also be produced.

Construction Materials for Rubber Tubing

Rubber tubing finds use in a wide range of applications. As such, manufacturers make it from numerous materials—with varying characteristics—to accommodate the requirements and restrictions of different industries, equipment and applications. Some of the most common materials employed in the construction of rubber tubing include:

- Butyl Rubber: This material offers many advantageous properties, primarily that of very low gas permeability. This material is used extensively where low gas transfer is key, such as in pneumatic bladders, etc.

- EPDM: This material maintains its stability across a fairly broad temperature range, though not as broad as inorganic elastomers such as silicone. It also demonstrates resistance to aging, chemicals, steam and water, ozone, and weathering. It’s resistance to aggressive bleach cleaning agents has increased its usage in military Nuclear, Biological, and Chemical (NBC) applications.

- Neoprene (Also known as Chloroprene): One of the original manufactured elastomer products, this material has similar properties as EPDM, but has been replaced by EPDM in many applications due to the improvements that EPDM offers.

- Nitrile (also known as Buna-N, NBR or HNBR): This material exhibits resilience, resisting damage from aging, abrasion, heat, oil, and tearing and is used extensively in applications with exposure to hydrocarbons.

- Silicone and Fluorosilicone: With the broadest temperature range of any elastomer, these materials are suitable for use in environments involving low or high temperatures, fire, electricity, and/or sanitary conditions. Fluorosilicone offers the added advantage of being resistant to many types of fuels.

- Fluorocarbon Elastomers (Also Known As Viton or Flourel): Though these elastomers don’t have the temperature range of inorganic elastomers, they have a very broad spectrum of resistance to aggressive chemicals.

- Sponge Rubber: Available in many of the above elastomer bases, This closed-cell material offers shock-absorbing properties that make it ideal for use in controlled compression applications.

Vanguard Products’ custom compound formulations provide precise engineered performance and tight tolerance adherence, without breaking the bank.

We use special processes to manufacture unblemished, round tubing in a variety of hardness from very soft (20 Shore A) to stiff (85-90 Shore A) with wall thicknesses as low as 0.010”. Vanguard’s high-precision, cost-efficient, and ISO 9001:2015–certified production facilities create products at the greatest levels of quality and efficiency.

In addition to manufacturing bulk extrusion, we also provide cost-effective secondary operations such as cutting, bonding, and O-ring fabrication.

Applications of Rubber Tubing

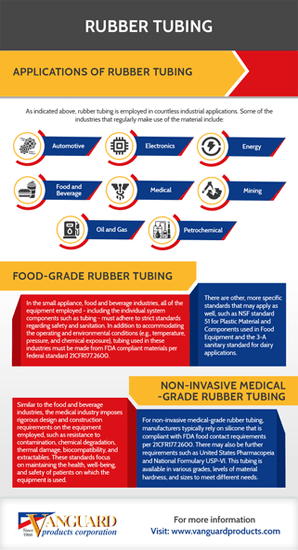

As indicated above, rubber tubing is employed in countless industrial applications. Some of the industries that regularly make use of the material include:

- Automotive

- Electronics

- Energy

- Food and Beverage

- Medical

- Mining

- Oil and Gas

- Petrochemical

Below we go into more detail about the rubber tubing used in the food and beverage and medical industries.

Food-Grade Rubber Tubing

In the small appliance, food and beverage industries, all of the equipment employed—including the individual system components such as tubing—must adhere to strict standards regarding safety and sanitation. In addition to accommodating the operating and environmental conditions (e.g., temperature, pressure, and chemical exposure), tubing used in these industries must be made from FDA compliant materials per federal standard 21CFR177.2600. There are other, more specific standards that may apply as well, such as NSF standard 51 for Plastic Material and Components used in Food Equipment and the 3-A sanitary standard for dairy applications.

Non-Invasive Medical-Grade Rubber Tubing

Similar to the food and beverage industries, the medical industry imposes rigorous design and construction requirements on the equipment employed, such as resistance to contamination, chemical degradation, thermal damage, biocompatibility, and extractables. These standards focus on maintaining the health, well-being, and safety of patients on which the equipment is used.

For non-invasive medical-grade rubber tubing, manufacturers typically rely on silicone that is compliant with FDA food contact requirements per 21CFR177.2600. There may also be further requirements such as United States Pharmacopeia and National Formulary USP-VI This tubing is available in various grades, levels of material hardness, and sizes to meet different needs.

Capabilities and Ranges for Rubber and Silicone Tubing

Vanguard designs all products to a range of industry requirements. Our production capabilities include:

- Single, coextrusion, and triextrusion capabilities

- Multi-lumen extrusion at varying hardnesses

- Multiple material/color extrusion

- Insert extrusion

- Diameters of 0.010–3+ inches

- Custom formulation for assets such as:

- Mechanical properties

- Chemical resistance

- Temperature resistance

- Thermal conductivity

- Electrical conductivity

- Color matching

- Thicknesses of 0.010 inches or more

- Bonding

- O-Ring fabrication

- Special put-ups

- Special packaging

- PSA application

Choose Vanguard Products for High-Quality Rubber Tubing

Vanguard focuses on supplying the best tubing material to meet your needs. We manufacture rubber tubing that provides optimal performance in an extensive range of applications, industries, and environments.

If you need high-quality rubber tubing, turn to the experts at Vanguard Products. We offer standard and custom rubber tubing suitable for use in a diverse set of industries, including food and beverage and medical. To learn more about our tubing products and services, visit our About Us page. Contact us today and allow one of Vanguard’s professional engineers evaluate your needs and provide you with the right solution.